Welcome to ALTEC

For more than 40 years now we have been a successful German manufacturer of high-quality aluminium scaffolding, aircraft and helicopter docks, aluminium pedestrian bridges, and make custom-made access solutions.

We manufacture with highly developed, state-of-the-art production systems, for example with fully automatic welding robots. As a specialist in aluminum welding, ALTEC achieves consistently high welding quality, which is guaranteed by EN 1090 certification. The quality of the products is crucial to be able to work safely at height. We have a dedicated product development team that ensures the company maintains its position as an industry leader by continually updating and improving the access product portfolio. ALTEC stands for quality and reliability.

ALTEC SCAFFOLDING SERIES

Rollfix® – scaffold for DIYs with an excellent price-performance ratio

Product features:

- Lighter, faster and tool-free construction

- Available with footplates as standing scaffolding or with rollers as mobile scaffolding

- Platforms can be mounted at any height, in each spindle.

- ...

Technical specifications:

- According to DIN EN-1004-1, TÜV-tested and statically proven

- ...

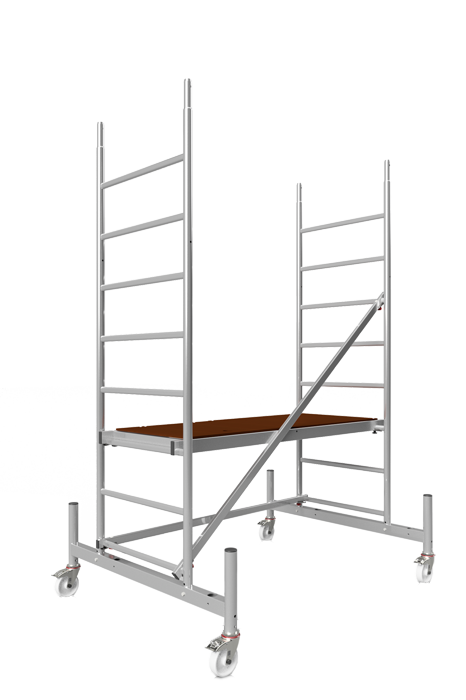

AluKlik® – The mobile folding scaafold in in widths 70 and 135

Product features:

- We offer our folding scaffold AluKlik in 0. 70 m and 1. 35 m width.

- The narrow variant (width: 70 cm) is supplied with telescopic triangular outrigger a working height of 5 m

- ...

Technical specifications:

- Mobile scaffold according to DIN EN 1004-1

- Maximum load: 450 kg

- ...

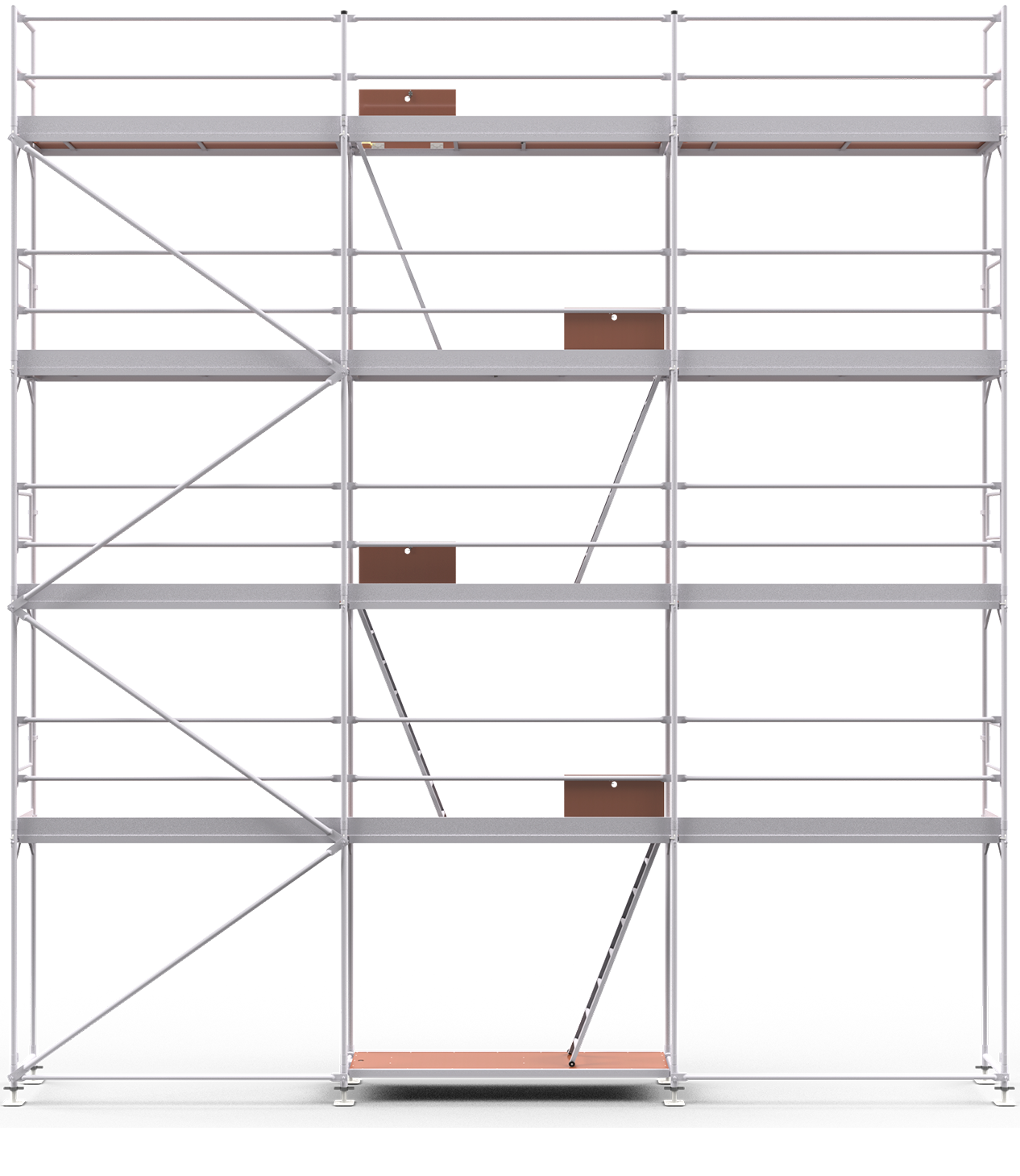

AluDeck® –Working platform for professionals and DIY-enthusiasts

Product features:

- AluKlik extension to large working platform

- Super lightweight, extremely resilient

- No tools required, easy and fast assembly

- Low transport volume

Technical specifications:

- Mobile scaffold according to DIN EN 1004-1

- Measurements 1,9 m x 3,9 m oder 3,0 m x 1,9 m

- Max. working height 3,8 m

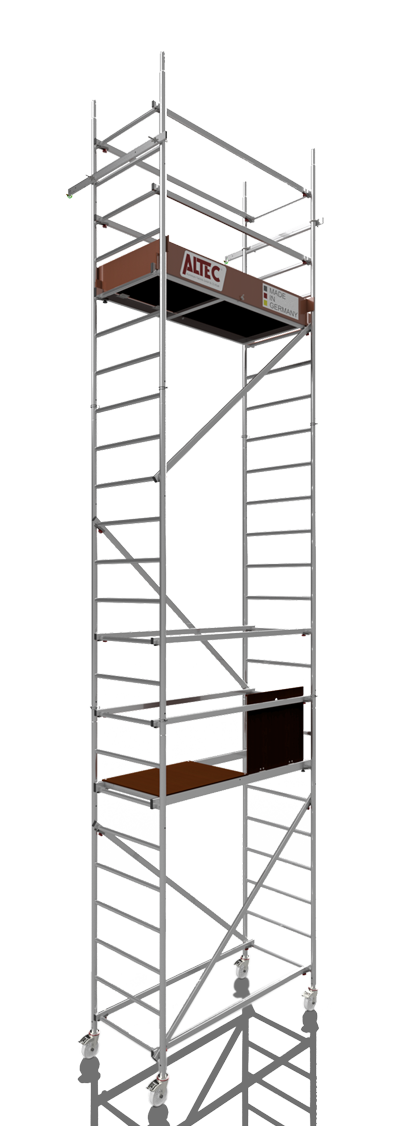

AluLight® – The mobile tower for professionals

Product features

- Working height up to 14 m

- Super lightweight, extremely resilient

- Includes 2-fold braked rollers with spindle for height adjustment (Ø 200 mm)

- High-strength self-locking aluminium claws, for fast and trouble-free assembly

Technical specifications:

- Mobile scaffold according to DIN EN 1004-1

- System length 2,5 m up to 300 kg per flooring stage

- System length 3,0 m up to 360 kg per flooring stage

ONLINESHOP

GERÜSTSHOP24

MOBILE TOWERS | FACADE SCAFFOLDING | WORK PLATFORMS |

DE-ICING PLATFORMS |

ROOF SCAFFOLDING uvm.

FAQ SCAFFOLDING

What work space is available to you?

(Dimension of the pavement or platform with 0. 7m or 1. 35m).Do you need your scaffolding with a specific work surface?

; Here is an overview of the floor covering sizes of all ALTEC scaffolding systems.

What is the maximum working height I can or must reach?

What is the maximum load capacity?

The maximum load evenly distributed on the platform is 200 kg/m² for all ALTEC scaffolds. This corresponds to load class 3 according to DIN EN 1004-1. A platform of 3. 0 m (AluLight) can therefore be loaded with a maximum of 360 kg.

Do you prefer a system with foot plates or wheels?

Rolling scaffolds are mobile and are used, for example, when the position of the scaffold is to be flexibly changeable. This mobility is ensured by rollers inserted on both sides at the lower end of the scaffolding. Scaffolds with foot plates offer a slightly better stability and always have spindles for height adjustment.

Should the scaffold also be able to be erected on stairs?

If this is the case, we recommend the systems RollFix und AluLight, but not AluKlik!

How often is the scaffold used or how much time do you have for erection?

For rare use the system RollFix is recommended, otherwise the AluKlik and AluLight plug-in systems. For daily use we recommend theAluLight Stair Tower with the fast and comfortable ascent over stairs.

What is the maximum weight of the scaffold?

All our scaffolds are recommended because they are made exclusively of aluminium.

Are ALTEC scaffolds certified?

All ALTEC rolling towers have been tested by TÜV-Süd.

How many triangular outriggers do I have to use?

For free-standing erection of the scaffold, four outriggers must be fitted. For installation on a wall, two brackets in combination with wall anchors are sufficient.

Why do scaffolding parts from other manufacturers not fit to an ALTEC scaffold?

The scaffolding parts of other manufacturers often have different dimensions. In addition, the static calculation and TÜV certification are based on the exclusive use of ALTEC scaffolding components.

Why is the maximum working height inside closed rooms 14 m higher than outside 10 m?

This requirement results from EN 1004 and is essentially due to wind loads.

At what wind strength is a rolling tower to be brought into closed rooms?

A rolling tower must be moved into a closed room from wind force 6 Bft or secured against overturning by other means.

What is the maximum permissible inclination of a rolling tower?

The max. permissible inclination is 1% and must be produced using spindles or spindleable base plates.

What kind of work is a rolling tower suitable for?

Areas of application in buildings:

- Painting work, also in stairwells or very high rooms

- Installation of lamps

- Electrical installation

- Wallpapering

Outdoor applications:

- Painting work on the facade

- Plastering of facades

- Anbringen von Wärmedämm-Systemen

- Installation of thermal insulation systems

- Cleaning work (gutter, roof tiles)

- Installation of windows

- Pruning of trees or hedges

Can I assemble a scaffold alone?

Yes, normally this is not a problem. The scaffolds presented here are also suitable for private use (RollFix), but especially for craftsmen, scaffolders and lessors (AluLight and AluKlik). Most scaffolds are designed in such a way that they can be assembled alone. Special tools are therefore not necessary.