Company philosophy

As a medium-sized company with more than 40 years on the market, we are proud to be one of the most important manufacturers of aluminium products in Europe. With our innovative scaffolding solutions, bridges and dock systems -Made in Germany- we rely on a recyclable material and offer real added value for a safe and comfortable everyday work.

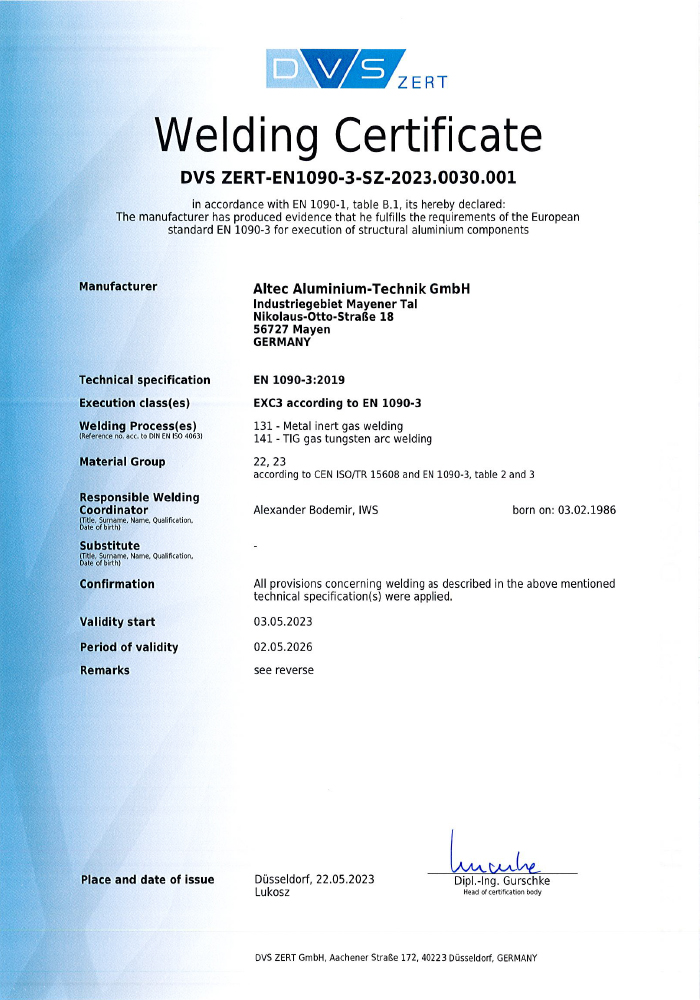

Our qualified employees have been manufacturing for you for over 40 years with commitment and utmost care. We produce according to European standards and we are certified by certified companies.

EXPERIENCE

As a dynamic and innovative company, our striving is aimed at progress, which has always determined our actions since our founding in 1985.

INNOVATION

About us

For more than 40 years now, we have been a successful manufacturer of high-quality aluminium scaffolding, aircraft and helicopter docks, process aluminium industrial parts and make special designs, e. g. for trade fair presentations or special constructions according to customer requirements. Every day about 40 skilled workers work on realising your products punctually and in the highest quality.

In our sawing department, there are several computer-controlled high-performance saws as well as self-feeding automatic saws available to cut the workpieces to the millimetre. In the CNC milling park, work is carried out on 4 computer-controlled milling machines simultaneously, economically and with the highest precision.

As an approved welding specialist ALTEC Aluminium-Technik GmbH has ten fully equipped manual welding cabins as well as three welding robots with four 360° swivel jigs each. Whether in the in-house construction or electrical department, ALTEC develops your concept and finds the most economical way. But this is only a small excerpt from the diversity of a company that has now been successfully producing exclusively in Germany for over a quarter of a century. Let's do it together!

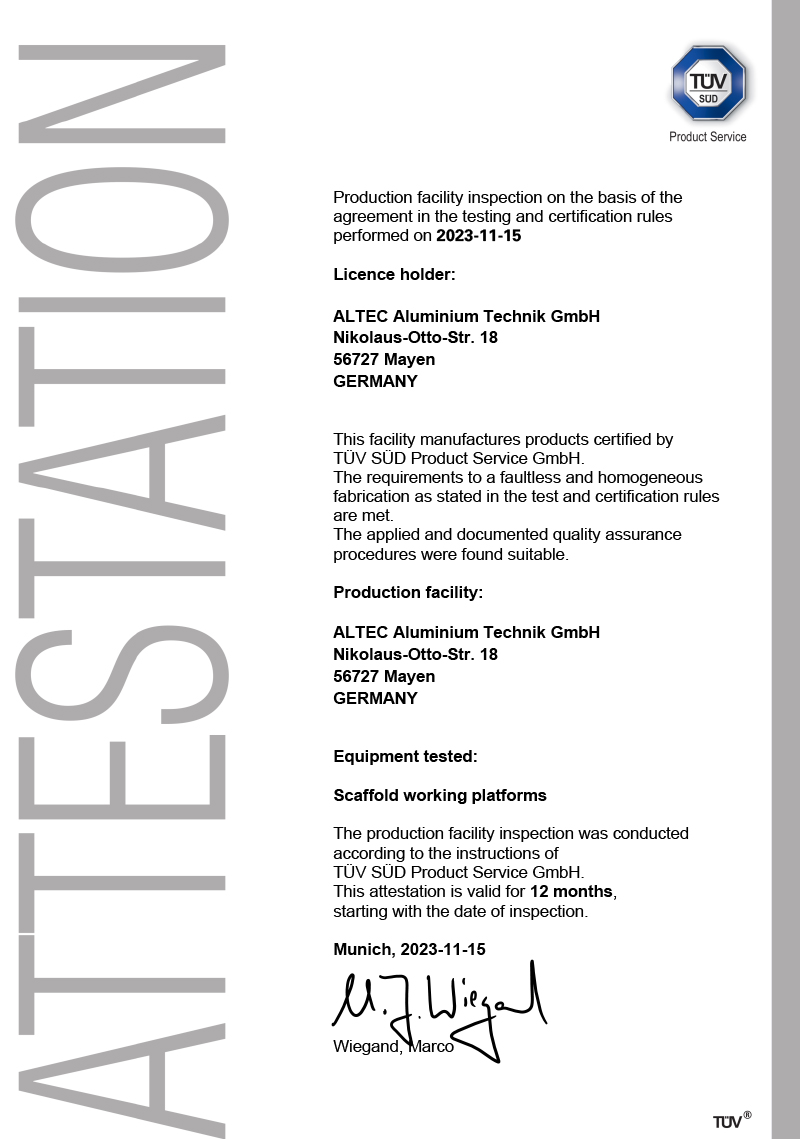

CERTIFIED QUALITY MANAGEMENT

Trust is good, but control is better

In the production of our scaffolding, we place high demands on quality and let ourselves be certified by certified companies. In addition to DIN-ISO certifications for safety standards, our scaffolding is also thoroughly tested by  . Thus, we guarantee maximum flexibility and safety for all ALTEC products.

. Thus, we guarantee maximum flexibility and safety for all ALTEC products.

Become part of our team

Career at ALTEC Aluminum-Technik GmbH

We are still looking for staff to strengthen our team, for an internship, training or part-time or full-time.

Just click here.

ALTEC News

Cooperation with partners, update of the machine park, and much more.

ALTEC in Mayen under new management

With experience into the future: Sven Seeger takes over as managing director at ALTEC Aluminium-Technik GmbH in Mayen. We continue to focus on progress ‘Made in Germany’ and the highest level of expertise in aluminium and steel processing.

Article about pipe processing from Blechnet

This article is about tube processing and how the purchase of a BLM Group LT7 has changed laser processing. (german)

Entry of Fronius welding technology at ALTEC

As automation progressed, a specific aluminum framework part (AlSi1, two millimeters) that was now required in large quantities was to be transferred from manual production to robotic welding. In particular, the focus here was on the high welding speed in order to gain a competitive advantage. At the same time, the construction should be joined with the greatest possible process reliability. As a specialist in thin sheet metal and aluminum applications, Fronius had the opportunity to assert itself against the competition in 2018: ALTEC had found the best possible solution for itself with the Fronius CMT (Cold Metal Transfer) process. CMT has particularly high welding speeds, especially in the thin sheet metal sector. As a result, Fronius managed to establish itself in ALTEC's production.