Kategorie

Artikelnummer

ATC073

Zertifikate

Our bridge references

ALTEC Aluminium-Technik GmbH boasts a wealth of successfully completed aluminum bridge projects. Our bridge systems are used throughout Germany. The wide range of customized solutions underscores our expertise and flexibility in implementing customized bridge structures. You can get an idea of our aluminum bridges here.

Advantages of an ALTEC aluminium bridge

-

Long service life due to the aluminium alloys used

-

Excellent price/performance ratio due to the use of a modular construction system

-

Maintenance and corrosion-free due to the material used

-

Fast bridge assembly within a few hours with subsequent, immediate commissioning

-

Short delivery times and low transport costs due to low weight

-

Minimal maintenance costs even after decades

-

The aluminium bridges are 100 % recyclable

Powder coated Bridge

Our Services

-

1. Planing

-

2. Statics

-

3. Production

-

4. Assembly

-

5. Preparation of the bridge book

Technical execution

-

When constructing the bridge, we always comply with EN 1090 Parts 1 and 3 in conjunction with Eurocode 9. If required, planning and execution can be carried out in accordance with other standards.

-

The bridges are designed as standard for a load of 500 kg/m². If necessary, a higher load can also be taken into account.

-

Framework are manufactured according to customer requirements either as screw or welded constructions. Special profiles with various alloy variants are used.

-

The bridge transitions are made by means of a grinding plate.

-

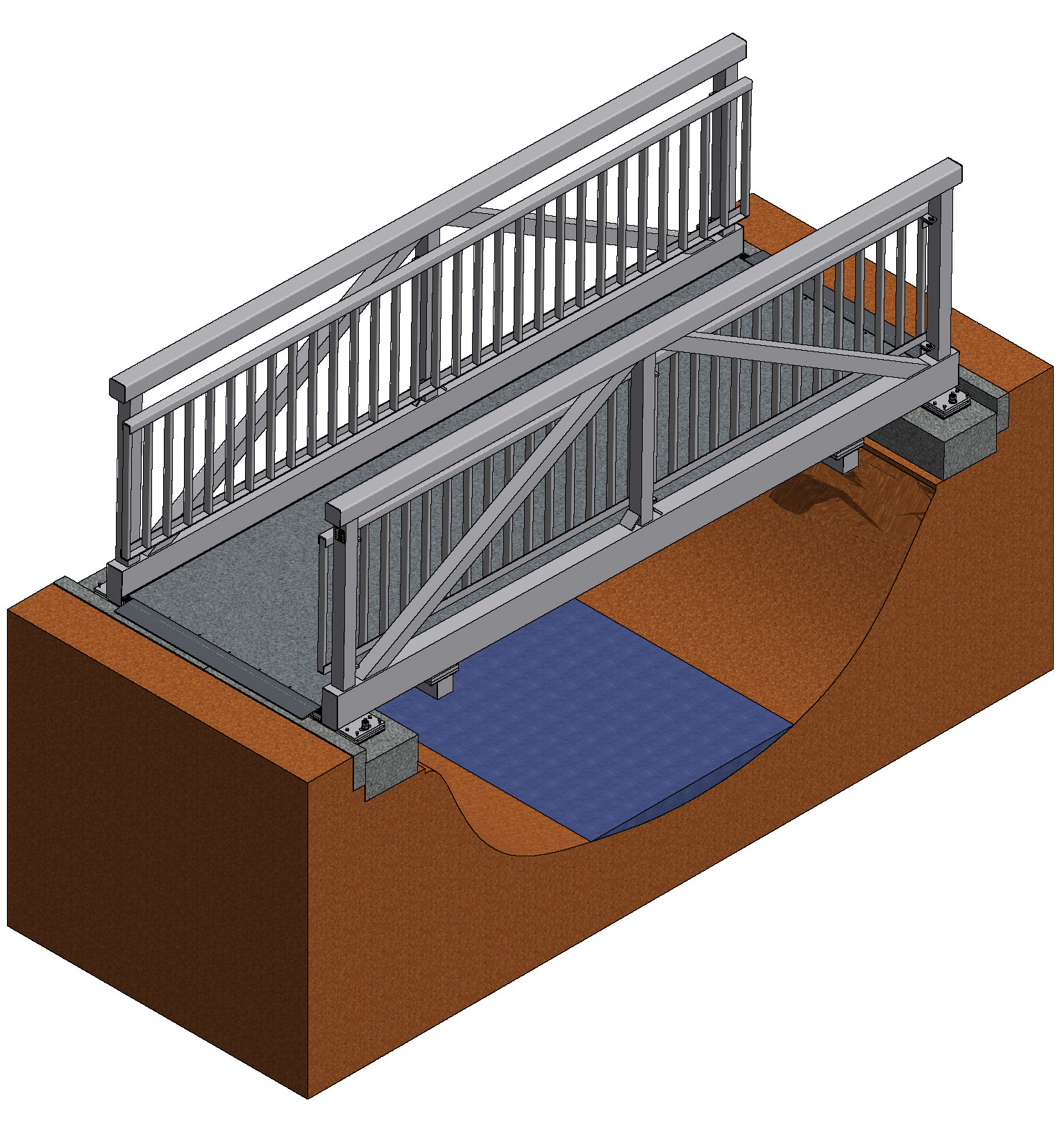

The bridge balustrades are made of aluminium railings, which are installed between or next to the upper and lower chord of the framework. A version with glass and perforated sheeting is also possible.

-

The bridge is completely manufactured in the factory, transported to the assembly site as a complete assembly and lifted in within a few hours using lifting gears.

The bridge is transported to its destination by truck.

Lifting the bridge with a truck-mounted crane

Lifting the bridge with an excavator

Lifting the bridge with an excavator

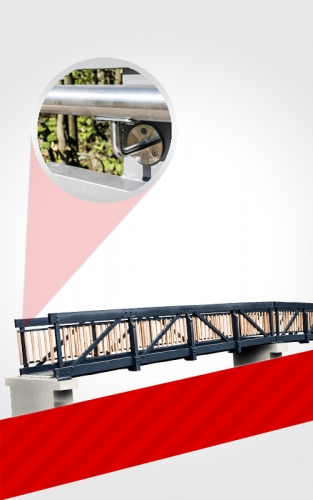

Anodized bridge

Railing connection

A railing extension matching the bridge is also possible.

A railing extension matching the bridge is also possible.

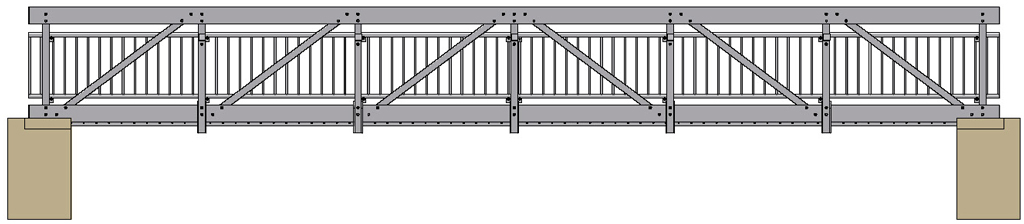

Types of construction

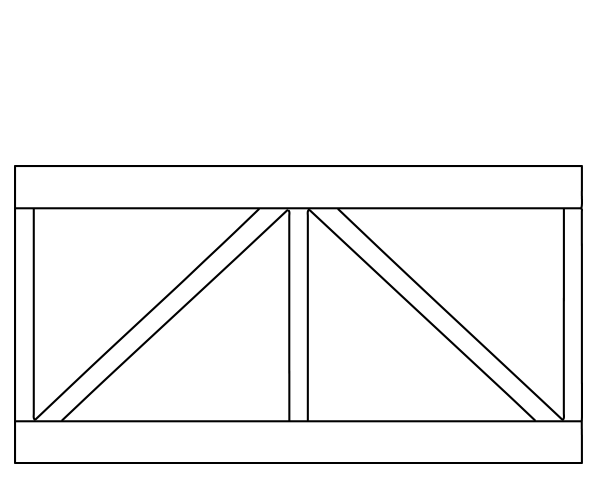

Frame bridges

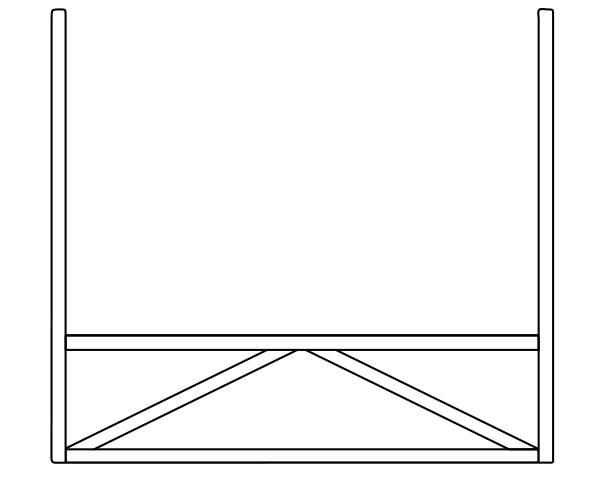

Construction cross section

In the case of a trussed bridge, the structural structure is the load-bearing structure.

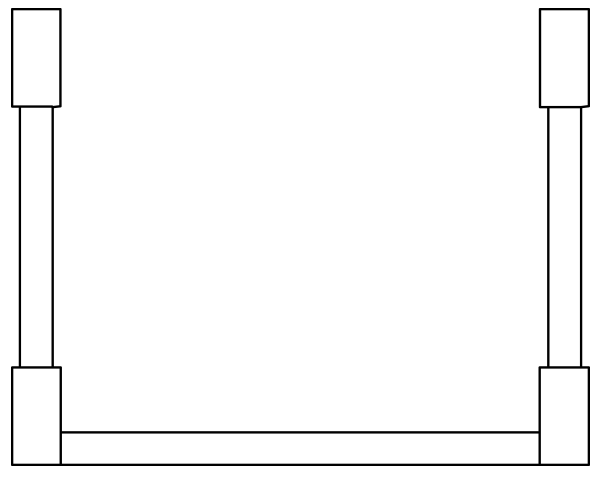

Trough bridges

Construction cross section

The carriageway slab is arranged between the main girders.

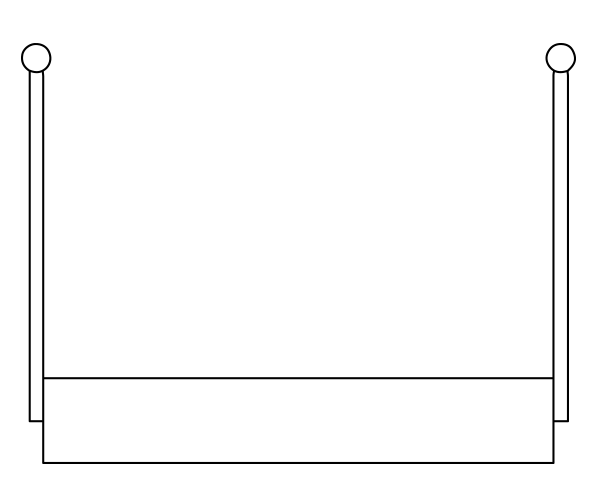

Hollow box bridges

Construction cross section

The hollow box is a girder whose cross-section encloses a hollow space.

Special constructions

Construction cross section

Custom-made products according to customer requirements

Surface design of frame bridges

-

► Weather-resistant and offshore suitable epoxy coating consisting of primer, colour shade according to desired RAL shade and clear coat, if required with anti-graffiti protection

-

► Anodized coating

-

► Powder coating to the desired RAL colour, if required with anti-graffiti protection

Colour examples

LIght grey

Dark blue

Light green

Dark green

Railing material

-

Aluminium filling bar railing with epoxy coating

-

Larch wood as bar railing

-

Perforated sheet

-

Safety glass

-

Vertical steel cables

Filler bar railing aluminium

Filler bar railing aluminium Filler bar railing larch wood

Filler bar railing larch woodTread material

-

Aluminium structural planks, if necessary in combination with noise-reducing 2K epoxy resin/polyurethane double coating with quartz sand sprinkling, up to the highest slip resistance of class R13 and the desired RAL colour

-

Gratings made of galvanized steel, mesh size according to customer requirements

-

Glass fiber reinforced composite planks of slip resistance class R11

2-component epoxy resin / polyurethane double coating with quartz sand scattering

Stainless steel handrail

Use and application of our bridges

- Cyclist and pedestrian bridges

- Port facilities

- Viewing platforms

- Railway crossings